ROMAG's patented circuit technology creates an

exceptionally powerful magnet for its size, as explained below.

Background Information: Regular Magnets

|

|

Single Regular Magnet

An individual magnet has two poles

(a "North" and a "South"),

and there's a magnetic force (" flux") radiating all around it.

This is shown in the cross section of a donut-shaped magnet to the

left. This magnetic flow occurs around the entire magnet.

|

|

Two Regular Magnets

The North pole of

one magnet is attracted to the South pole of another.

Only the

magnetic force directly between the two magnets actually pulls the two

magnets together - the majority of the pull goes into the air and doesn't

contribute to the strength of the magnetic system. |

The ROMAG Innovation

|

|

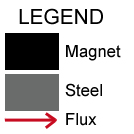

Things you

need to know

- Magnetic flux is what pulls two magnets together (or holds steel).

- It flows from the North pole of a magnet to the South

pole

- Steel is a better conductor of magnetic flux (force) than air

- Flux follows the path of least resistance (i.e. - it will flow

through steel instead of through the air if that's an option)

|

|

"Open" Circuited Magnet

In the patented ROMAG magnets, almost all of the magnetic force

is used to hold the two parts of the magnet system together - very little is wasted.

First, a conductive steel plate is attached to a donut-shaped magnet.

This along with a second steel plate is a "magnet system."

When separated

("open"), the magnetic flux flows into the air around the magnet and does

no work.

|

|

"Closed"

Circuited Magnet

When closed, however, almost all of the

magnetic force flows within the magnet system because the two steel plates create a "short

circuit".

The magnetic flux is now put to use holding the two

sides together instead of being wasted into the air.

This results

in a magnet that's very powerful for its size. |

| |

|

ROMAG Engineering

|

|

Balance is important.

If there isn't enough steel for

the strength of the magnet, some of the flux will escape into the air and will

be wasted (i.e., it won't help hold the two pieces together).

ROMAG

engineers use advanced mathematical modeling to ensure that the quantity of

the steel and its configuration are optimized to prevent wasted flux, which

would decrease the holding power of the magnet.

|

|

|